Products

Ferrous Scrap

Heavy Melting Steel (HMS)

Ferrous scrap is any discarded or recycled material primarily composed of iron and steel.

Distinguished by its magnetism and durability, ferrous scrap is the most commonly recycled

Ferrous metals are used in a vast range of products, and their scrap is often categorized

based on its source and composition.

Heavy Melting Steel (HMS):

Comes from thick, heavy steel such as beams and industrial equipment from construction and demolition.

Cast Iron Scrap:

Recycled cast iron from automotive parts, machinery, and cookware.

Auto Scrap:

Vehicles that have been salvaged for their steel and iron content.

Industrial/Prompt Scrap:

Leftover metal from manufacturing processes and factory production.

Light Metal Scrap (LMS)

Non-Ferrous Scrap

Aluminium Scraps

Aluminium UBC, or Used Beverage Container, refers to the

high-quality Aluminum scrap collected from recycled drink cans. This post-consumer

material is a highly valuable commodity in the recycling industry due to its purity and

endless recyclability.

Aluminium Extrusion 6063

Material composition

The material is based on the 6063 Aluminum alloy, known for its corrosion resistance and good surface finish.

Main elements

Silicon (Si) at 0.20–0.60% and Magnesium (Mg) at 0.45–0.90%.

Contaminants

Iron (Fe) content should be a maximum of 0.35%, with other elements like copper, zinc, and manganese also tightly controlled.

International standards

The Institute of Scrap Recycling Industries (ISRI) specifies grades for Aluminum scrap, and the code for 6063 extrusion scrap is TATA

Aluminium Alloy Wheels

Aluminium Casting Scrap

Clean casting scrap:

This is free of contamination like paint, steel, or non-metallic parts. Because it requires minimal processing, it is one of the most valuable grades.

Dirty or mixed casting scrap

This contains non-metallic components like steel bolts or rubber bushings, or has been painted or coated. It must be sorted and cleaned before being recycled, which lowers its value.

Diecast scrap

This is generated specifically from die-casting operations and includes defective products or off-cuts. Its alloy content can vary significantly depending on the industry.

Automotive scrap

A significant source of casting scrap is discarded vehicle parts, such as engine blocks, cylinder heads, and transmission cases.

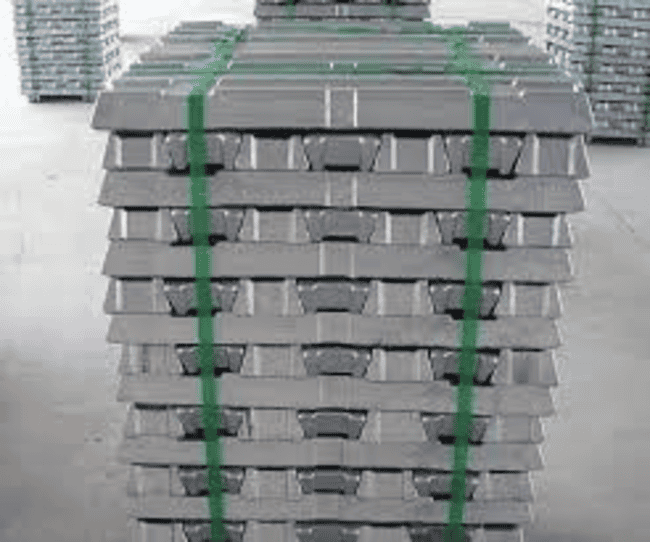

Aluminium Ingots – A7 Grade

High purity

A minimum of 99.7% Aluminum content with very low levels of impurities like iron (Fe) and silicon (Si).

Lightweight

Like other Aluminum products, A7 offers a high strength-to-weight ratio, which is crucial for reducing mass in manufacturing applications.

Corrosion resistance

Aluminum naturally forms a protective oxide layer that shields the metal from the elements, ensuring long-term durability.

High thermal and electrical conductivity

These properties make A7 suitable for components requiring efficient heat dissipation or electrical transmission.

Recyclability

Aluminum is highly sustainable and can be recycled repeatedly without a loss in quality, making A7 an environmentally friendly choice.

Malleability and formability

The material can be easily shaped and formed for various manufacturing processes.

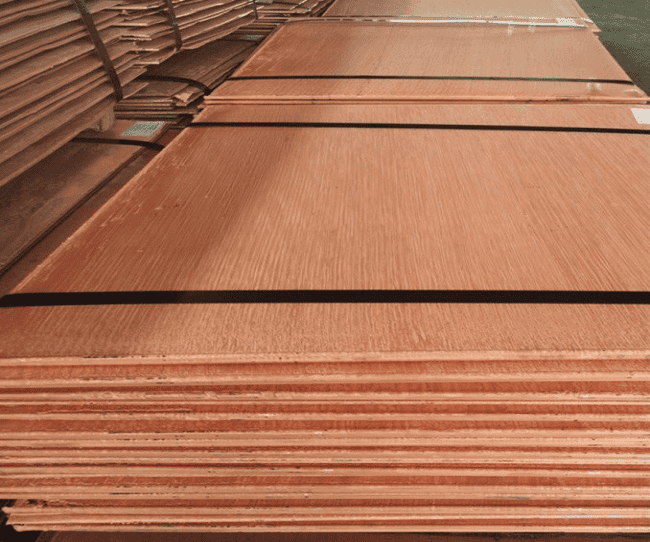

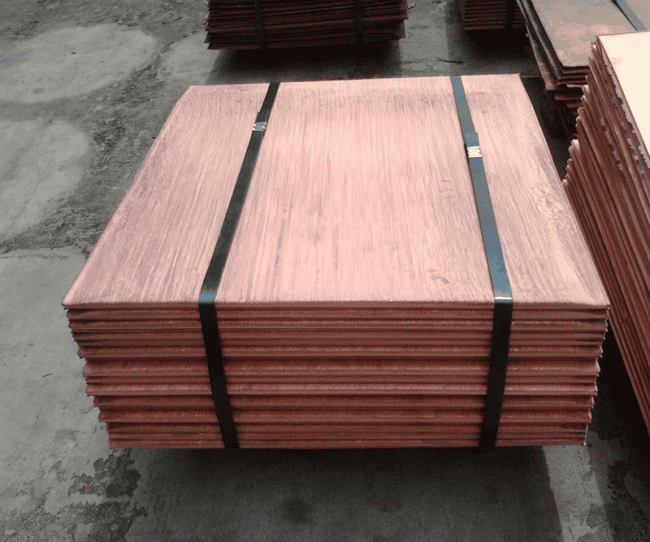

Copper Cathode

Production process

The production of copper cathodes involves several stages, which differ depending on the type of copper ore (sulphide or oxide).

Mining and concentration

Copper ore is first extracted from a mine, crushed, and ground into a powder. The copper-containing minerals are then concentrated into a slurry.

For oxide ores (hydrometallurgy):

1) The concentrated ore undergoes leaching, where a weak acid solution dissolves the copper content.

2) The resulting copper-rich solution is then treated in a process called electrowinning. An electric current causes pure copper to deposit onto starter cathode plates, resulting in a high-purity product.

For sulphide ores (pyrometallurgy):

1)The concentrated ore is processed in a smelter at high temperatures to produce blister copper, which is about 99% pure.

2) This blister copper is cast into large anodes and placed in an electrolytic bath.

3) Through electrolytic refining, an electric current moves copper ions from the impure anode to the pure copper starter sheet (the cathode). Impurities settle to the bottom as "anode slime

Stainless Steel Scrap

A copper cathode is a form of high-purity copper produced through the electrolytic refining of copper ore. These large, rectangular plates, with a typical purity of 99.99%, serve as the primary raw material for manufacturing a wide range of copper products.

Production process

The production of copper cathodes involves several stages, which differ depending on the type of copper ore (sulphide or oxide).

SS 304

Corrosion resistance: Grade 304 is composed of approximately 18% chromium and 8% nickel, which provides excellent resistance to corrosion.

Recyclability: It is 100% recyclable. Recycling stainless steel reduces the need for virgin materials and helps cut down on energy consumption during manufacturing.

High alloy content: The nickel and chromium content are valuable in the scrap metal market and fetch a higher price than common ferrous scrap.

SS 316

Composition

316 stainless steel contains 16–18% chromium, 10–14% nickel, and most importantly, 2–3% molybdenum. It is the added molybdenum that sets it apart from grade 304, providing superior resistance to chlorides and other corrosive chemicals.

Higher value

Because of its higher nickel content and the presence of molybdenum, 316 stainless steel scrap fetches a higher price than 304 grade.

Non-magnetic

As an austenitic stainless steel, grade 316 is non-magnetic. You can use a magnet to help confirm its non-magnetic properties, which distinguishes it from lower-value, magnetic stainless-steel grades like 430.

Testing for molybdenum

If you are unsure whether a piece of stainless steel is 304 or 316, you can purchase a molybdenum test kit. The test involves applying a testing solution that reacts with the molybdenum in 316, causing a brown stain to appear. If it is 304, there will be no reaction.

EXCLUSIVE COMMODITIES

Premium Global Products

Jasmine Thai Rice

Thai Jasmine rice is a long-grain rice variety famous for its distinct floral aroma, soft texture, and slightly sweet flavour. It is a staple of Thai cuisine and an important export crop.

- Aroma: The signature fragrance is caused by the compound 2-acetyl-1-pyrroline, which is also found in pandan leaves. It is often described as resembling pandan or popcorn.

- Texture: When cooked, the grains are tender and moist with a soft, slightly sticky texture that clings together but is not as sticky as glutinous rice.

- Flavour: It has a subtle, nutty, and slightly sweet flavour.

- Appearance: Uncooked grains are long and slender. The term "Jasmine" likely refers to the color of the cooked rice, which is white like the jasmine flower, rather than the scent.

White Thai Jasmine rice is a source of carbohydrates, protein, and dietary Fiber. Whole-grain

brown jasmine rice offers additional nutrients and is a richer source of:

- Vitamins: Contains B vitamins like thiamin (B1), niacin (B3), and pyridoxine (B6), which help convert food into energy.

- Minerals: Includes magnesium, manganese, iron, and selenium.

- Antioxidants: Colourful varieties of jasmine rice contain phytonutrients and antioxidants that protect cells from damage.

Topson Global Group Company sources best quality Thai Jasmine Rice from the

renowned Thai Rice processing factories in Thailand, for export to various countries.

Sugar ICUMSA 45

ICUMSA 45 Sugar is widely recognized as one of the highest-quality sugars available

on the market. Known for its exceptional purity and consistent white color, it is a

highly refined, granulated sugar suitable for various food and beverage industry

uses. ICUMSA Sugar undergoes stringent processing to ensure it meets the highest

standards, making it ideal for consumption and industrial applications. Its versatility

and quality make it a preferred choice for manufacturers, retailers, and consumers

worldwide.

Topson Global Group Company sources best quality Sugar from the renowned sugar

factories in Thailand, for export to various countries.

Industrial Grade Urea

Industrial grade urea, also known as technical grade urea, is a refined form of the organic compound primarily used for non-agricultural industrial applications. Unlike agricultural-grade urea, which is often treated with chemicals for slower release as a fertilizer, industrial grade urea is processed to a higher level of purity. This higher purity and more consistent composition make it suitable for manufacturing processes with tight specifications.

- Appearance: A white crystalline solid or powder.

- Purity: Contains fewer impurities, especially lower levels of biuret, than agricultural grades. Biuret can be toxic to some plants and interfere with certain industrial reactions.

- Solubility: Highly soluble in water.

- Nitrogen content: High nitrogen content, typically around 46%.

- Hygroscopic: Readily absorbs moisture from the air.

Within the industrial category, even higher-purity grades exist for more sensitive uses:

- Automotive Grade Urea (DEF): A high-purity, 32.5% urea solution used in Selective Catalytic Reduction (SCR) systems to reduce nitrogen oxide (NOx) emissions in diesel engines.